Ideal for wind-energy applications

Overview

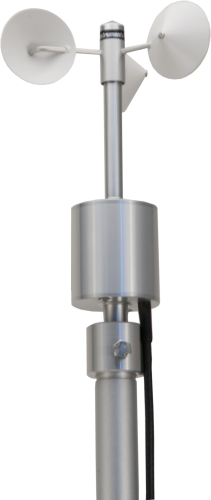

The A100LK is an anemometer for general meteorology and for wind-energy surveys. Its low power consumption and wide power-supply range make it popular for remote locations with no access to ac power, and its pulse/frequency signal is ideal for use with Campbell Scientific dataloggers. The sensor is constructed with anodized aluminum alloys, stainless steel, and weather-resistant plastics for long life. It is used as part of our WMS100 wind-monitoring system.Read More

Benefits and Features

- Low power consumption

Images

Detailed Description

Rotation of the A100LK’s three-cup rotor is electronically converted to pulse output signals proportional to wind speed. The A100LK produces a higher rate of pulses per revolution (up to 13) compared to relay-based sensors, making it suitable for wind surveying where turbulence needs to be estimated.

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Dataloggers

| Product | Compatible | Note |

|---|---|---|

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR350 | ||

| CR6 | ||

| CR800 (retired) | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR850 (retired) |

Additional Compatibility Information

Data Logger Considerations

The A100LK uses one pulse count channel on the data logger.

Programming

The A100LK is read by the PulseCount Instruction in CRBasic and by Instruction 3 (Pulse Count) in Edlog. Wind speed measurements can be taken and processed with any of the data loggers.

Specifications

| Sensor | 3-cup anemometer |

| Measurement Description | Wind speed |

| Signal Type/Output | Electronic pulse |

| Range | 0 to 77 ms-1 |

| Threshold | 0.15 ms-1 (starting speed 0.2 ms-1, stopping speed 0.1 ms-1) |

| Maximum Speed | 77.22 ms-1 |

| Accuracy | 1% ±0.1 ms-1 |

| Distance Constant | 2.3 m ±10% |

| Calibration Data |

Supplied for anemometer and rotor at one test speed to an accuracy of ±1% at +15°C. (12 Vdc supply and an analog output load of 1 MΩ) |

| Operating Temperature Range | -30° to +70°C |

| Rotor | 15.2 cm (6 in.) diameter three-cup rotor |

| Supply Voltage | 6.5 to 28 Vdc |

| Current Consumption |

2 mA maximum 1.6 mA typical (no output load) |

| Power-up Time | 5 s |

| Surge Protection | Vector PC3L2 anti-surge module fitted |

| Housing Diameter | 5.5 cm (2.2 in.) |

| Height | 19.5 cm (7.68 in.) |

| Weight | 490 g (17.3 oz) including 3 m (10 ft) cable |

Documents

Brochures

Manuals

Frequently Asked Questions

Number of FAQs related to A100LK-L: 1

-

No. Cables are attached and sealed on the sensor by the manufacturer. Whenever possible, purchase a sensor with the desired cable length. Alternatively, a new sensor can be purchased with a foot of cable and then spliced onto the existing cable. Splicing cable together, however, increases the likelihood that water may enter the cable and cause shorting, corrosion, and some other potential issues, which in turn can cause measurement issues. Because of the potential issues, do not splice any sensor cable without first contacting Campbell Scientific to discuss the sensor in detail.

Case Studies

As part of the United Nations Development Programme's (UNDP) Crisis Prevention and Resilience Building component,......read more

Privacy Policy Update

We've updated our privacy policy. Learn More