Instrumentation

We offer a variety of products that can be used to create systems for Vehicle Testing. Many of the major components used to create these systems are listed below. Please let us know if we can help you configure a system.

More Details about Our Vehicle Testing Systems

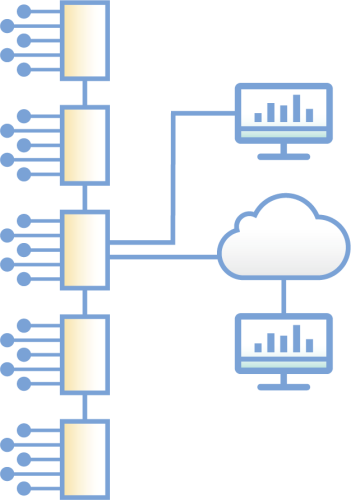

Data Acquisition for Vehicle Testing

We offer a full line of data acquisition systems. Scan rates can be programmed from every few hours to 100,000 times per second, depending on the system model. Measurement types, processing algorithms, and recording intervals are also programmable. Our systems can also store data transmitted from the vehicle's on-board computer via CANbus, allowing time-synchronized storage of vehicle computer data with the data acquisition system's independently measured data.

On-board instruction sets contain programmed algorithms that process measurements and output results in the desired units of measure. For example, data can be displayed as rainflow or level crossing histograms. These rainflow and level crossing algorithms allow processing for extended periods of time, not just a limited number of cycles. Our instruction sets also allow unattended measurement and control decisions based on time or conditional events.

Sensors for Vehicle Testing

Because our VDAS are compatible with almost every commercially available sensor, our systems give you the freedom to use the sensors that best meet your application. Most sensors connect directly to our dataloggers, eliminating costly external signal conditioning. Channel types include analog (single-ended and differential), pulse count, switched excitation, continuous analog output, anti-aliasing filter, and digital I/O.

Typical sensors used with our systems include: thermocouples, pressure transducers, pulse pickups, flow transducers, potentiometers, strain gages, load cells, digital switches, accelerometers, LVDTs, and tilt sensors. Our configurable dataloggers, the CR9000X-series, allow you to choose modules with the channel types that best fit your application. The number and type of channels on most of our VDAS are expandable using multiplexers and other measurement peripherals.

Data Retrieval

On-site communications interfaces for retrieving, storing, and displaying data include direct connection to a PC or laptop, PC cards, storage modules, and a datalogger keyboard/display. A heads-up-display is also available for data display when driving a vehicle. Telecommunication options include short-haul, telephone (landline, cellular, and voice-synthesized), radio frequency, multidrop, and satellite.

Software

Our PC-based support software simplifies the entire data acquisition process, from programming to data retrieval to data display and analysis. Robust error-checking ensures data integrity. We can even help you post your data to the Internet. RTDAQ is a full-featured package that is included with the CR9000X systems. RTDAQ is also compatible with our CR1000, CR3000, CR800, and CR850 dataloggers, although the software is purchased separately.

RTDAQ features include:

- ShortCut Program Generator for easy-to-use, step-by-step programming assistance.

- Variety of windows for monitoring datalogger data in near-real time, including Fast Graph, Histogram Viewer, FFT Viewer, Table Monitor, and X-Y Plot.

- Historical display of data in time series, rainflow, level crossing, and FFT formats.

- Data collection in multiple data formats.

Testing Possibilities

Our data acquisition systems have been instrumental in testing the following:

General Testing

- Chassis monitoring

- Road noise

- Vehicle speed

- Steering

- Air bag

- Distance traveled

- Humidity

- Hot and cold soaks

- Wind tunnel

- Altitude

- Geographic location

Fuel System Testing

- Line pressure

- Tank pressure

- Temperature

- Flow

Climate Control Testing

- Ambient air temperature

- Supply air temperature

- Solar radiation

- Fan speed

- Interior temperature

- Time to comfort

- A/C on and off

- Refrigerant pressures

Suspension Testing

- Strut pressure

- Spring force

- Travel

- Mounting point stress

- Deflection

Brake Testing

- Line pressure

- Pedal pressure/travel

- Line/pad temperature

- ABS

Engine Monitoring

- Oil pressure

- Oil temperature

- Water pressure

- Water temperature

- Fuel injector timing

- Crank position

- RPM

- Noise level

- Heat detection

- Catalytic converter

- Cooling fan speed

- Manifold pressure

- Manifold temperature

- Exhaust gas temperature

Case Studies

The Space Shuttle Endeavor carried the CR10 and CR9000 data loggers into orbit as part......read more

Phil Ayliff Products of Warwickshire, England, is a world leader in the development and manufacture of......read more

Campbell Scientific data-acquisition systems are used extensively for vehicle testing by the UK-based auto manufacturer,......read more

Instrumentation engineers from Daewoo Motors used a Campbell Scientific CR7 Measurement and Control System during......read more

The Aston Martin used a CR7 Measurement and Control System for environmental testing on its......read more

Documents

Brochures

Related Product Categories

Articles and Press Releases

Privacy Policy Update

We've updated our privacy policy. Learn More

Customise a System

In addition to our standard systems available, many of the systems we provide are customised. Tell us what you need, and we’ll help you configure a system that meets your exact needs.